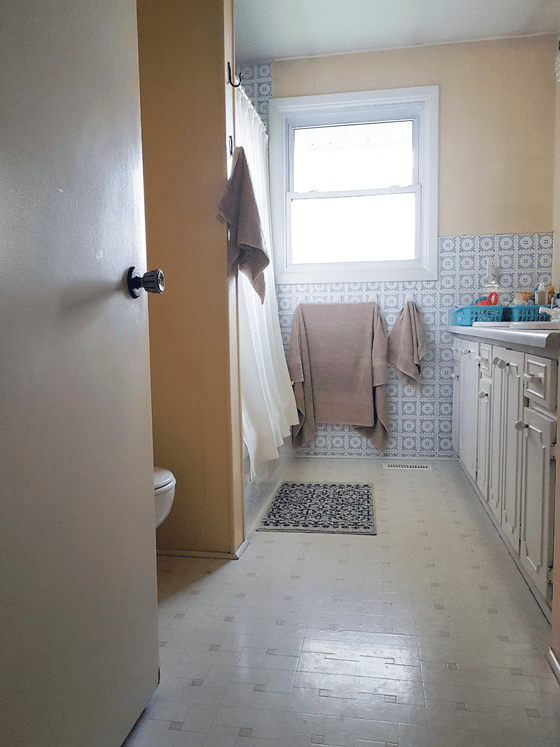

“A huge main bathroom with double sinks, a huge vanity and tons of storage. (The cracked sink, 1970s tile, painted paneling on the walls and Care-Bear-colour-palette on the counter top are examples of potential.)”

This is what I wrote about the main bathroom when I first introduced it on the blog thirteen and a half years ago.

I finally fulfilled that potential. The main bathroom renovation is done. And it is so beautiful.

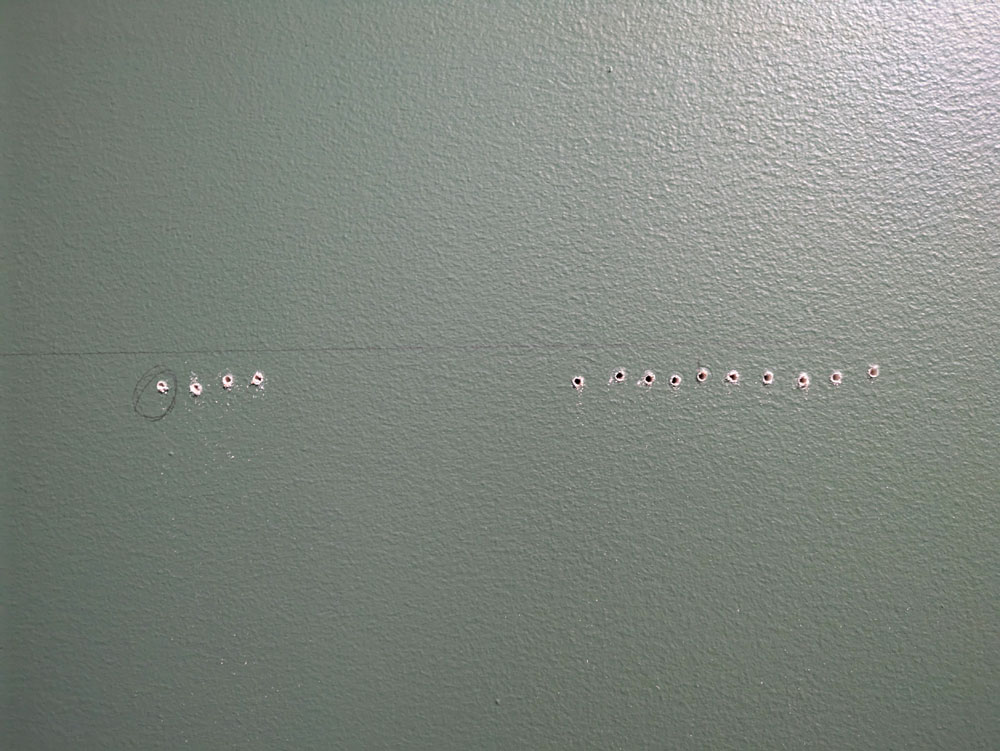

I took everything out–the fixtures, the two tubs, the fake paneling, drywall, insulation, Care-Bear counter top–and redid it all.

My philosophy for the past 13 years was if I was going to renovate, I wanted to do it completely and ensure the end product was exactly what I wanted.

It is.

I’m going to dive into all the details. But first, here are a few before and afters.

Bathroom before and after

All the details on our new country style bathroom

Behind the walls are new wiring, pipes and insulation. The walls themselves are beautiful pine V-groove paneling. A big upgrade from the fake sheets that were there before. With every renovation in this house, I’m trying to add more farmhouse style, and I felt like the paneling was a good way to do that in the bathroom.

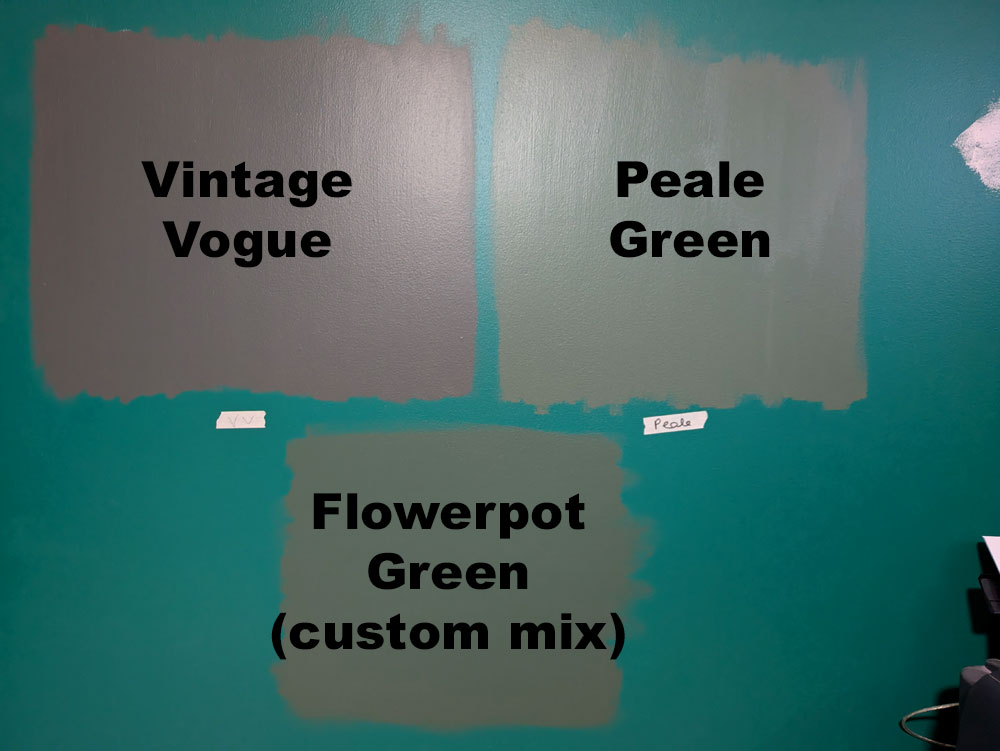

I kept the walls white (Benjamin Moore Cloud White) to keep the look fresh. The white paint highlights the V-groove which gives a subtle texture and interest to the walls. Plus going with white allows the other parts of the bathroom to stand out.

I can’t decide what stands out most to me. Is it the huge wood storage hutch? The sparkly taps? The beautiful marble? The veins of the tile? The leafy shower curtain?

I love how all of the elements of the bathroom work together so well.

For the floor and tub walls, I chose very large tiles with strong veining. The large size is very practical for cleaning (minimal grout!). The finish is matte, which feels appropriate for the farm and contrasts with some of the other sparkly bits in the bathroom. The tiles themselves are also full of contrast with grey lines snaking and swirling over the warm white background. I also had in-floor heat installed, which makes the floor so comfortable.

Accompanying the tiles is our marble on the shower ledge and countertop. This marble is a statement. It’s dark and light and dramatic. Adding to the drama is the beautiful ogee edge, the sculpted backsplash and sidesplashes and the leathered texture. I’m so glad I added these details.

I’m also glad I added the ledge all along the side of the tub. It was a simple adjustment to make at the construction stage. The ledge gives us so much storage and I much prefer the look over a niche. Bumping the tub out by 4 inches didn’t impact the function of the bathroom, and we still have plenty of space between the tub and vanity.

The vanity is exactly the design I had in mind for years. Drawers, drawers and more drawers. I’m so pleased I was able to find it off the shelf. At first, I was concerned that the drawers would be too small. They are quite shallow and narrow. However, they work really well for most things–the perfect amount of space for toothbrushes, hairbrushes, makeup and lots of space to separate things out. Certain containers or bottles don’t fit. Fortunately we have taller storage elsewhere (more on this below).

The vanity led to the one change of plans I needed to make in the renovation. The sinks I had ordered turned out to be too big. Fortunately, the company I worked with to source all of the fixtures quickly supplied another option, and I was able to make the exchange. The sinks we ended up with are quite small, but they are adequate for most bathroom tasks, like washing our hands and brushing our teeth. Most important they fit with the vanity, the taps, the counter.

The taps were another spot where I was trying to create some of that historic farmhouse feeling. From the beginning I knew I wanted old style cross handle taps. That’s exactly what I found: very traditional and a little bit fancy. Their sparkly finish, cross handles, high arc add so much brightness to the bathroom.

In my initial plan for the bathroom, I had expected to have more of a mix of metals. I had planned for the lights and vanity hardware to be on-trend brass or gold. But as the bathroom came together, I couldn’t make the finishes work. I decided to go with the simple chrome hardware that came with the vanity, and that made the light fixture decision easy–sparkly silver there too.

We still have a bit of a mix with a few hits of black in the hutch hardware, hooks and curtain rod.

Instead of mixing metals, I decided to warm things up with a lot of wood accents. This is another touch of farmhouse style. The mirrors were the very first thing I bought for the bathroom. The wood frame and arched top add softness to the other square lines in the room.

I had always envisioned wood towel rings and accessories. Thanks to Facebook marketplace, some refinishing and a little bit of my own construction, I was able to make it happen.

Of course, the big wood storage hutch is another standout. As I wrote 13 years ago, the bathroom had tons of storage, mainly a large linen closet. Unfortunately, its open shelves were ugly and not super functional. Replacing the closet with this hutch adds so much to the bathroom.

Storage of course. I designed the hutch to have 6 super deep drawers. Towels, bottles, soap, medicine, first aid supplies and more all easily fit in the hutch. The upper section with its four shelves holds towels, toilet paper, sheets, blankets with lots of room to spare.

Beyond storage, the hutch adds so much beauty. The maple wood looks perfect for the farm.

The final finishing touch was the shower curtain. This is our only bit of colour in the bathroom. I chose a watery blue leaf fabric that has a beautiful mix of dark and light that echoes some of the tones in the tile and counter. I sewed the curtain myself. I wanted it to be traditional, so I added some pleats at the top. This gives the curtain lovely fullness. It’s also full length from ceiling to floor which makes the bathroom feel so much taller.

This bathroom renovation was not quick. I began taking the room apart in April and finally hung the shower curtain at the end of September. Beyond those 5 months is the 13 years.

It was worth the wait.

I documented the bathroom renovation on my Instagram as well. You can check out all of the videos at Part 1, Part 2, Part 3 and Part 4. Thanks to everyone for following along on the blog and on social media and cheering me on through this project.

Bathroom sources:

Tub

Sinks

Taps

Mirrors

Tile

Lights

Vanity

Wall panelling

Baseboard

Casing

Paint

Marble counter and shower ledge – Arctic Ocean

Hutch – Custom

Shower curtain – Custom DIY

Towel rings, bars, paper holder – Facebook Marketplace

Trades & Suppliers (with sincere thanks)

Waterdown Plumbing

Agentis Electric

Almar Flooring Inc. (tile installer)

Centura (tile supplier)

Granite By Design

EMCO Burlington

Cambridge Crown & Trim

Mennonite Furniture & Gifts